In the fields of water conservancy engineering and river regulation, selecting the appropriate water-retaining structure is a key decision-making point. The traditional steel dam gate and the increasingly widely used hydraulic dam represent two different technological approaches. Each has its own strengths and weaknesses in terms of structure, operation, and comprehensive benefits.

The steel dam gate, also known as a steel flap gate, typically relies on a mechanical linkage structure or a hydraulic system for overall tilting or lifting, belonging to the category of rigid movable dams. Its structure is robust and can withstand significant impact. However, it usually requires substantial opening/closing force, and once a malfunction occurs, repair is difficult and costly.

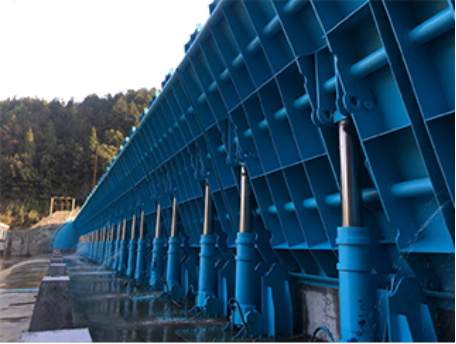

The core of the hydraulic dam lies in the hydraulic system hidden beneath the dam foundation, which drives the dam face panel to achieve flexible lifting from 0 to 90 degrees. The dam face is usually made of reinforced concrete, providing structural strength. This design allows the hydraulic dam to remain stable while retaining water and to respond quickly when flood discharge or water level adjustment is needed.

In terms of reliability, the mechanical structure of the steel dam gate is relatively simple and direct, but in rivers with high sediment or debris, the hinge joints are prone to jamming. Although the hydraulic system of the hydraulic dam is more precise, modern technology has significantly improved its sealing and anti-pollution capabilities. Furthermore, its main power unit is located on the bank, facilitating maintenance.

Regarding landscape and ecology, when laid flat, the hydraulic dam body rests close to the riverbed, allowing unobstructed flood discharge and having a smaller impact on the natural river landscape and fish migration. When the steel dam gate is lowered, its steel structure may partially protrude above the riverbed.

In terms of cost, the initial steel investment and installation costs for large steel dam gates are typically higher. The initial investment in civil works and the hydraulic system for a hydraulic dam can also be substantial. However, its operational energy consumption is lower, and in the long term, it can achieve efficient water resource utilization through flexible scheduling, offering significant long-term benefits.

Industry experts point out: "The choice between dam types requires comprehensive consideration of the specific river's functional positioning, hydrological conditions, sediment situation, and budget. Steel dam gates still have advantages in situations requiring extremely high structural strength, while hydraulic dams are becoming a more popular choice in modern urban river regulation projects that emphasize ecological friendliness, operational flexibility, and landscape harmony."