Product Overview

Melting & Deicing device from BIC exchanges heat with the stratum water body and disturbs the water body in front of the sluice, so that the water body cannot form an ice core. Even in the severe cold winter, it will not form an ice layer, which effectively solves the frozen problem before the sluice. For the detaield melting and deicing solution, welcome to contact us!

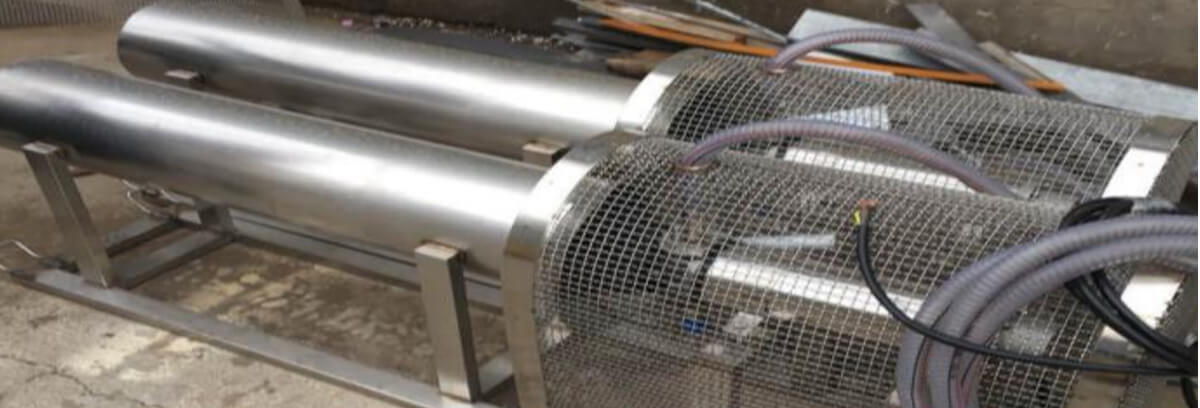

The structure of the device mainly includes high performance motor, integral stainless steel submersible anti-ice erosion shell, conveying cylinder, air storage chamber, bleed tube, impeller, water delivery bucket, bracket, cover net and other components. At the same time, MDD is equipped with a propeller blade, which stirs with water while the equipment sucks in the air, so that the water is quickly spread.

The high-performance motor quickly mixes the compressed air in the air intake pipe and air storage chamber with the water body. Finally, the high-speed rotating impeller produces strong axial thrust and radial stirring, which crushes the compressed air in the water body to form tiny particles. Nano bubbles are oriented horizontally and pushed out into the water body through the conveying cylinder. The flow of micro-nano bubbles impacts, stirs, and pushes the water flow out to fan-shaped radiation. The accelerated bubbles diffuse and mix into the body water, making the water molecules less likely to condense in cold temperatures.

Product Specification

| Shell material | Integral stainless steel submersible melting & deicing shell |

| Device weight | About 30kg |

| Rated power | 0.75- 3 kW |

| Rated voltage | 220V/380V |

| Push flow distance | 20m water surface width, 5m river length range |

| Dissolved oxygen ability | 1.1-4.2 kgO2/h |

| Motor power | 1- 4 hp |

| Air intake | In the case of a water depth of 1m,oxygen intake up to 20 - 51 m3/h |

| Circulating water | 260 - 780 m³/h |

| Air-entraining rate | 22000 m³/h |

| Installation height | The top of the equipment is 3 meters below the water surface for the best effect |

| Other equipment | When the water depth exceeds one meter, equipment needs to be equipped with brackets and counterweights. |

Project Advantages

Wide Ice Breaking Range

Each device can control water surface width of more than 20m, so that no ice cover is formed within the river length of nearly 5m. The powerful water flow can push the water flow to push the air bearing water body beyond 30m.

MDD extracts relatively high temperature water in the middle and lower part of the river, which increases the temperature of the surface water. By pumping gas, the existence of ice nuclei in the water body can be effectively reduced, so that freeze in the water can be avoided as much as possible. Studies have shown that piping hot milk freezes before cold milk. This effect called the Mpemba effect. The reason for the Mpemba effect is that the hot milk contains less air. At the same time, the horizontal jet generated by MDD makes the surface water body strongly turbulent, which can reduce the formation of ice blossoms.

Compact Structure, High Inflation Rate, Fast Ice Melting Rate

When MDD is running in the water, it can not only increase the dissolved oxygen to the greatest extent, but also push the water flow to fully exchange the bottom water and the surface water and expand the exchange water body forward. In the process of the water exchange, the micro-nano bubbles produced by device stay in the water for a long time and are constantly disturbed in the water. MDD can suck in air at a rate of up to 22,500 cubic meters per hour, which ensures an efficient inflation rate and ice melting rate.

Safe and Reliable, Energy Saving and Environmental Protection, No Secondary Pollution To The Water Body

Since the air contains 21% oxygen, plus a large number of anions and cations generated when micro-nano bubbles burst in the water body, MDD can make the water body clear in a short period of time. So as to achieve the function of water purification. MDD combines the pressure water jet method and the compressing air blowing method at the technical level, which increases the equipment efficiency and reduces the energy consumption. Generally, the power of a piece of equipment is below 3kW.

Simple Construction, Convenient Operation And Maintenance

The installation of MDD is convenient and concise, requiring only 5 installation workers with high water quality and 1 high-voltage electrician, and 1 manned vessel. In order to prevent large-scale collisions in the water from damaging the equipment, it is only necessary to remove the equipment for maintenance during the flood season and put it back in place after the flood season. In the case of not involving flood control during the flood season, the equipment can always be placed underwater. Daily maintenance only needs to check whether the cable is damaged, whether the motor grille is deformed, and whether the motor is running normally. Later operation and maintenance is convenient, saving money and effort.

Wide Range of Applications

In winter of high latitudes, rivers, channels will freeze, forming water ice, floating ice and ice caps. Ice conditions often change continuously with changes in temperature, the changing of ice conditions will significantly change the movement of water currents. If it is not properly controlled, it may cause some hydraulic structures, such as gates, steel dams, rubber dams, etc. To be damaged by ice erosion.

Comparing Similar Technologies

| Melting & Deicing Device(MDD) | Artificial ice breaking | Electric heating method | Insulation board method | Pressure water jet method | Compressed air blowing method | |

| Melting range | Wide ice breaking range.Each device can control water surface width of more than 20m, so that no ice cover is formed within the river length of nearly 5m.The powerful water flow can push the water flow to push the air bearing water body beyond 30m. | The melting range is restricted by artificial factors and is only suitable for places where the thickness of the ice layer is not large. | The melting range is small, the ice melting effect is unstable, and only a part of ice layer can be melted. | The melting range is small, which can only improve the melting conditions of the local ice layer. | Irregular melting range | The smooth melting range and high degree of automation, |

| Melting speed | Fast ice melting rate. In the process of the water exchange, the micro-nano bubbles produced by device stay in the water for a long time and are constantly disturbed in the water. MDD can suck in air at a rate of up to 22,500 cubic meters per hour, which ensures an efficient inflation rate and ice melting rate. | The melting speed is restricted by artificial factors. | Low electric heating efficiency and slow melting speed. | Low melting efficiency and slow melting speed. The insulation board is brittle material that is not easy to save, and the anti-icing effect is unstable. | The disturbance range is large, and the melting speed is affected by the power of equipment. | The melting speed is fast, but the corresponding air compressor load and power increase. The melting speed is affected by the power. |

| Safety | It is safe and reliable, and will not cause the secondary pollution to the water body. Since the air contains 21% oxygen,plus a large number of anions and cations generated when micro-nano bubbles burst in the water body, MDD can make the water body clear in a short period of time. So as to achieve the function of water purification. | The work environment is difficult, and workers have certain risks when working. | The equipment is in direct contact with water, which poses certain safety hazards. | No noise, no pollution and high safety. | The equipment is arranged underwater and there are certain safety hazards. | The pipeline is line and the equipment is arranged underwater, which poses certain safety hazards. |

| Energy consumption | Increased work efficiency and low energy consumption. Generally, the power of a piece of equipment is below 3kW. | Workers are labor intensive, laborious, and inefficient. | Power consumption is huge. | No energy consumption, energy saving and environmental protection. | Submersible pumps require high power and high energy consumption. | The blowpipe has a large submerged water depth. Under the corresponding airflow conditions, the amount of water raised is higher, the temperature of water raised is higher, and the anti-icing effect is good, but the load and power of the air compressor need to be increased. |

| Difficulty in installation and operation | The installation of MDD is convenient and concise, requiring only 5 installation workers with high water quality and 1 high-voltage electrician, and 1 manned vessel. | It is easy to operate. | The operation is simple and effortless,the degree of automation is high. | This is no piping required and it is easy to operate. | Compact structure, this is no piping required and it is easy to operate. | The off-plan houses occupy a large area, piping is troublesome, and installation is greatly affected by the water. |

| Operation maintenance and overhaul | In order to prevent large-scale collisions in the water from damaging the equipment, it is only necessary to remove the equipment for maintenance during the flood season and put it back in place after the flood season. In the case of not involving flood control during the flood season, the equipment can always be placed underwater. Daily maintenance only needs to check whether the cable is damaged, whether the motor grille is deformed, and whether the motor is running normally. Later operation and maintenance is convenient, saving money and effort. | This is no follow-up operation maintenance and overhaul | The maintenance and repair procedures of equipment installation and door slots or door pages are complicated. | After installation, there is no need for later operation and maintenance. The overhaul process is complicated. | The water pump is easy to break and is installed under water, and the maintenance procedures are complex. | The pipeline is long, with many points, and the maintenance is greatly affected by the water surface, and the process is complex. |

| Investment cost | The degree of automation is high, the labor cost is greatly reduce, and the investment cost is greatly reduced because of its low energy consumption and wide ice-breaking range. | High labor cost and low general investment cost. | High degree of automation and low labor cost. However energy consumption huge and investment and operation maintenance cost is high. | Low labor cost and large one-time investment. | Low labor cost, high equipment power requirements. | Large equipment power required, complex installation and operation maintenance and high investment cost. |